Choosing a Very Narrow Aisle (VNA) application can be a feasible solution if you’re in need of more space or want to increase your warehouse density. With VNA you can go for double the number of pallets and 50% productivity increase.

VNA solutions have different requirements than wide aisle solutions. Here are some factors you should consider before making your choice.

When is the right time to narrow down your aisles?

VNA trucks have rotating forks making pallet retrieval easy which means they can operate in a wide variety of situations. Generally, though, pallets have a longer shelf life in this type of application and not the same turnover as with a reach truck setup. The breaking point would be if you are looking to generate more profitability. Reducing logistic costs is a priority for any company. Storage and warehousing are the main cost drivers in the supply chain.

The benefits of choosing a VNA forklift truck are:

• Better space utilisation and higher storage capacity.

• Alternative to warehouse extension or external storage.

• Lower cost per square metre.

• Higher productivity and throughput.

• Greater lift height.

• Lower travelling time in picking.

Why is warehouse flooring so important?

In warehouses and logistics facilities, the concrete slab and flooring are critical to running safe and efficient operations. Flooring standards are elevated for VNA solutions compared to traditional forklift operations. The ideal floor should be flat, showing no imperfections. Since VNA trucks have no suspension, every minor imperfection is amplified.

The narrow space between the aisles leaves no room for even the slightest leeway. Not even when the truck is static. When moving, the safety margin is even reduced by 40% due to the dynamic ratio. Imagine the domino effect impacts would create. For the driver’s comfort and safe pallet handling, any unevenness in the warehouse floor has to be taken out. Make sure the surface is resistant to deterioration and can withstand impact caused by the rolling of the trucks.

Should you have a guidance system?

To guarantee safe operations, the truck in-aisle movement needs to be guided using rails (mechanical guidance) or wires. Traditionally, the in-aisle position of the truck is maintained by a rail installed on either side of racking. The VNA truck is then equipped with side guidance rollers to keep the truck in a straight line while travelling along the narrow aisle. The various types of rail guidance are slightly safer as with this bolted system it’s more difficult for the truck to derail.

The most common or preferred option is to have the truck wire guided. This option is cheaper and easy to implement and clean. A wire buried in the floor produces a magnetic field which the machine detects and follows as a guide.

What extended safety measures should you consider?

The Personal Protection System (PPS) is a feature that activates an automatic slowdown and stop system at both ends of the aisle should the truck come across any obstruction along its path as it travels along the aisle.

Aisle indication is a smart way for the truck to recognise its position in the aisle, helpful to find locations. Sensors on the truck communicate with RFID (radio frequency identification) tags or magnets along the aisle.

Zone-dependent interlocks limit the speed, extended height or fork movement of the truck in certain areas of your warehouse, helping to avoid collision with ventilation shafts, sprinklers or any other overhead obstructions.

What should you consider before a warehouse redesign?

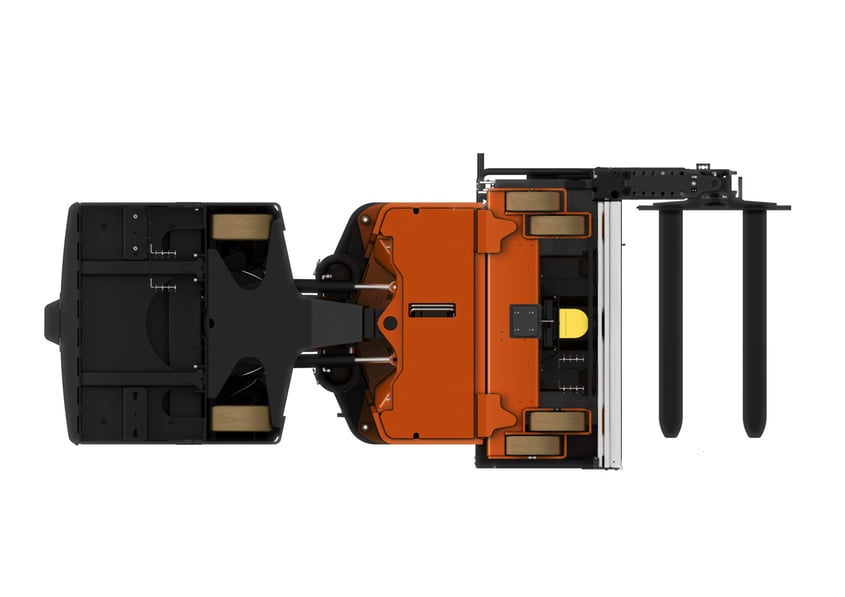

Very Narrow Aisle trucks help maximise warehouse space utilisation without expanding. The articulated frame of our trucks provides excellent stability and manoeuvrability, perfect for narrowing the aisles and increase your warehouse density, as we explained before.

Before you start redesigning your warehouse layout, think about these factors, as mentioned above:

- Determine the perfect aisle width and ceiling height

- Design an ideal floor for delicate warehouse and logistics operations

- Select the correct guidance system

Next to the VNA zone you will need to leave room for the horizontal transport and foresee pick & drop stations to transfer goods from the VNA storage to the horizontal transport zone. You should also decide if you want order picking done here.

As for racking, conventional racking will suffice. There are no specific requirements in a narrow aisle setting. Evidently, the racks will be built higher up so your ceiling height may need to be adjusted. This is a far less cumbersome intervention than expanding.

How can we help you?

Toyota Material Handling can offer business support and advice to deliver a complete solution built to match your operations’ needs. You can contact one of our experts here.