Keeping your fleet running optimally, while also managing costs, can be a challenge for fleet managers. This blog series we will reveal 3 cost-saving methods to help you discover new ways to save money while having more control over your fleet.

In this first blog post of the series, 'run your forklift fleet for less', we will cover battery management.

Save batteries, save money

Though often overlooked, fork lift batteries account for a significant cost of a fleet manager's budget. Proper forklift battery management will prolong the battery lifetime and avoid the cost of buying extra batteries during the contract period.

To extend the service life of your forklift batteries, you need to consider 2 things:

- Does your forklift battery type suit your operation?

- How are your forklift batteries charging?

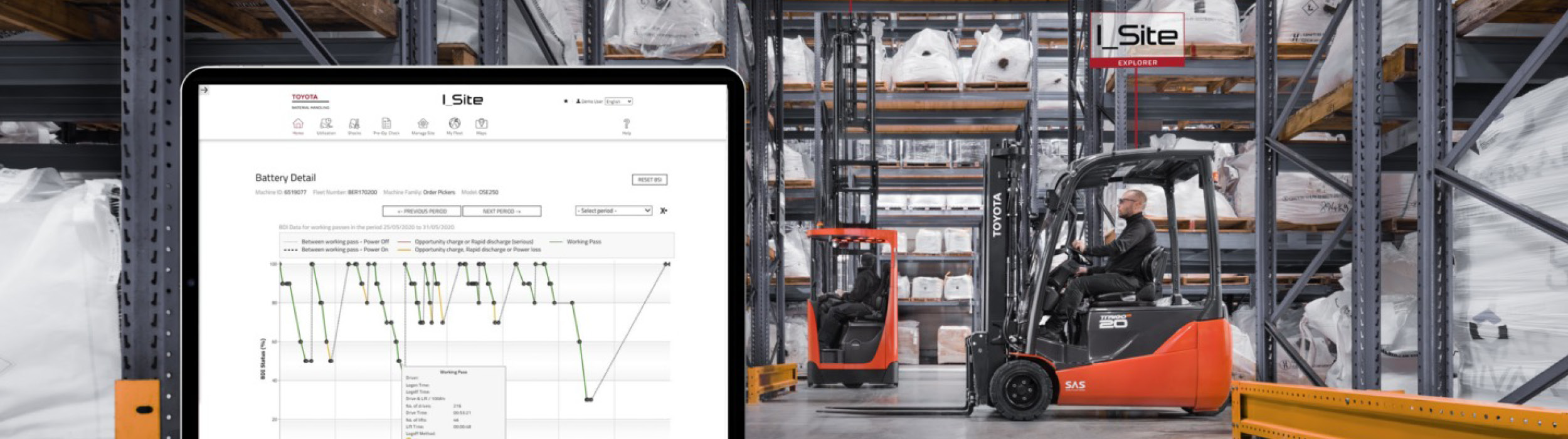

To help you understand and monitor your battery usage, the Toyota i_Site fleet management software connects to your material handling equipment and can provide you with access to a host of useful battery data.

Does the forklift battery type suit your operation?

- If your forklift truck uses lead-acid batteries:

Lead-acid batteries should be put on charge when they reach 20% discharge. This will keep the life expectancy of the battery at five years or more.

The life expectancy is affected by the charging frequency. If the battery is frequently charged for short period of time before it reaches 20%, (opportunity charging), the battery lifetime will decrease drastically, and you will need to buy a new battery much sooner and more often. - If your forklift truck uses lithium-ion batteries:

Lithium-ion batteries are more flexible when it comes to charging. Unlike lead-acid batteries, the life expectancy of a lithium-ion battery is not affected by charging frequency. In fact, opportunity charging is encouraged to maintain the uptime of your operation.

Our fleet management system, I_Site, automatically detects the battery technology used in your trucks. The I_Site Explorer package can also help you select the correct battery type for your operations: lead-acid or lithium-ion.

How are your forklift batteries charging?

Monitoring battery usage with regular checks at fleet level will help you to improve energy efficiency.

Toyota's I_Site fleet management tool allows you to easily view the battery charge/discharge cycle for each truck to be able to quickly flag up inefficient battery handling so you can take measures when needed. For example, it could highlight if you need to provide training on battery management to your forklift operators.

Using I_Site Explorer will enable you to check that your batteries are always fully charged when the trucks are idle. Doing this will ensure you don’t need to charge the battery when the truck is needed, therefore decreasing downtime.

With the right type of battery, charged optimally, you can use your trucks to full capacity while saving energy and costs.

Read more about how you can run your fleet for less with part 2: reduce damage costs and part 3: utilise your forklift trucks.