Managing your forklift service truck costs, while running your fleet optimally, can be a challenge for fleet managers.

We began our 'run your electric forklift truck fleet for less' blog series with advice on battery management, followed by ways in which you can control your damage costs.

In this third and final blog post of the series, we will explore vehicle utilisation to allow you to use your forklift trucks more efficiently.

Are you utilising your forklift trucks?

It is important to use your material handling resources efficiently for optimal productivity and cost.

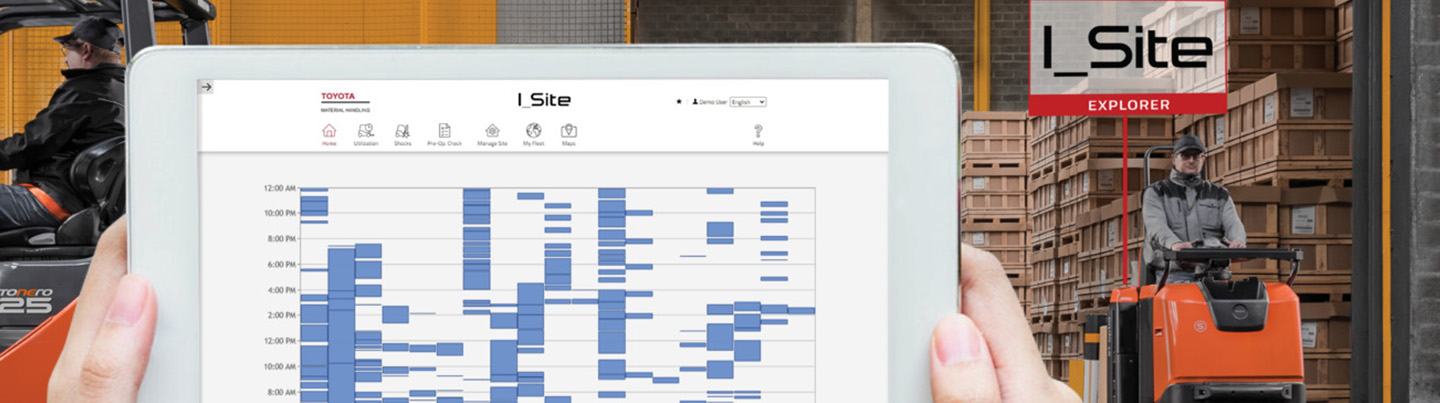

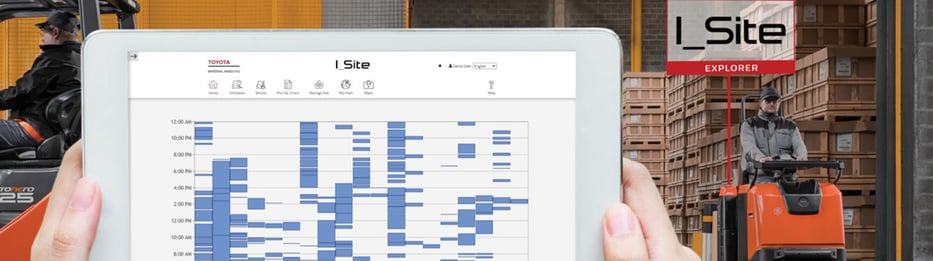

To decrease peak utilisation, avoid unnecessary investments, swap vehicles to improve their usage rate, or even remove a machine from your fleet list, I_Site generates machine utilisation charts so you can monitor and analyse the data to quickly identify bottlenecks or unused capacity and take action.

Are you utilising your forklift drivers?

As well as optimising your forklift truck usage, you need to consider the efficiency of your operator usage too.

Data taken from your connected vehicles with I_Site allows you to gain an understanding of allocated driver time and if you have too little, or too many, drivers to run your operation smoothly, so you can have more control and flexibility over your forklift fleet and operators.

What are my next steps?

Toyota's I_Site Explorer software is designed to help fleet managers achieve optimal use from their forklift trucks. It presents utilisation data about your fleet in an accessible visual format to help you manage your forklift fleet and operators.